2026 Top Aluminum Wire Coating Benefits and Applications?

The demand for Aluminum Wire Coating continues to rise in various industries. Market data shows that the global aluminum wire market is projected to reach USD 15 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5%. This increase is driven by the material’s lightweight, corrosion resistance, and conductivity properties. Aluminum Wire Coating plays a pivotal role in enhancing the longevity and efficiency of electrical applications.

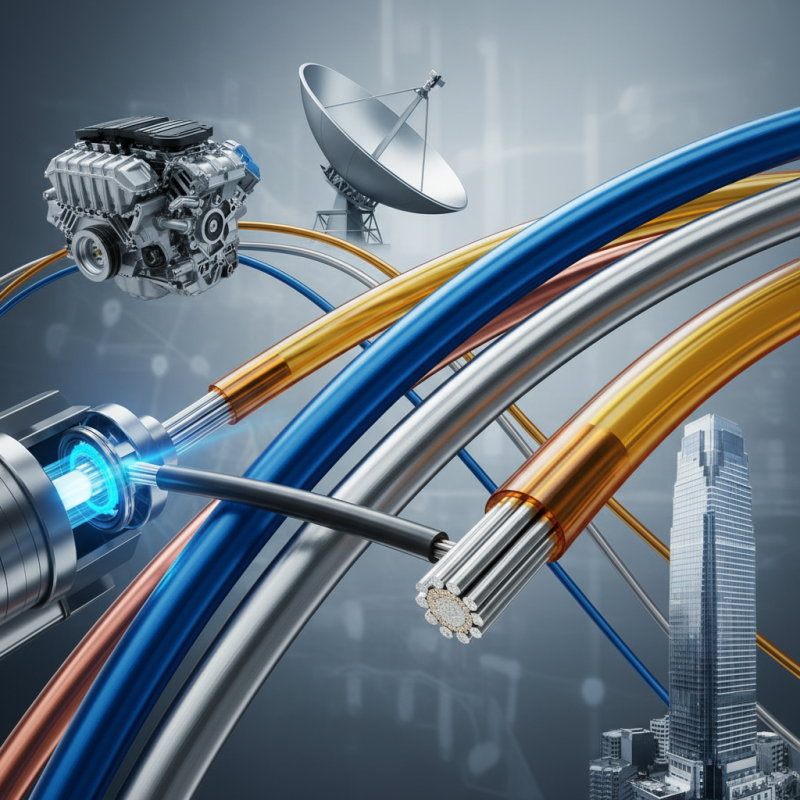

With applications ranging from automotive to aerospace and construction, Aluminum Wire Coating ensures improved performance. For instance, in the automotive sector, coated aluminum wires reduce weight, contributing to better fuel efficiency. Furthermore, in the telecommunications industry, the coating enhances signal reliability by minimizing interference. However, achieving the perfect coating consistency remains a challenge. Manufacturers often face issues with adhesion and durability, requiring ongoing research and innovation.

Industry experts emphasize the need for advanced formulations to maximize the benefits of Aluminum Wire Coating. Reports suggest that adopting new technologies can lead to greater efficiencies. As we explore the advantages and applications of aluminum wire coatings, it's essential to address these challenges. Manufacturers should prioritize developments that not only meet demand but also enhance performance and sustainability.

Top Advantages of Aluminum Wire Coating in 2026

In 2026, aluminum wire coating is gaining more attention due to its unique benefits. One major advantage is its lightweight nature. Compared to copper coatings, aluminum is significantly lighter. This can lead to easier handling and transport in many applications.

Another key benefit involves corrosion resistance. Aluminum coatings protect wires from environmental damage. This ensures a longer lifespan for electrical installations. Longevity matters, especially in demanding conditions like coastal areas.

Tips: Always consider application environments before choosing a coating. Not all environments are suitable for aluminum. For heavy-duty needs, reevaluating your choice is crucial. Additionally, keep in mind the installation method. It may affect the effectiveness of aluminum coatings.

Lastly, it’s worth noting that while aluminum coatings are beneficial, they're not always perfect. Issues like weldability and stretchability can arise. It's essential to carefully assess needs before making decisions. Proper evaluation leads to better results in the long run.

2026 Top Aluminum Wire Coating Benefits and Applications?

| Benefit | Description | Application | Key Advantages |

|---|---|---|---|

| Lightweight | Aluminum wire is significantly lighter than copper, making it easier to handle and install. | Electrical wiring for residential and commercial buildings. | Reduced installation costs and labor. |

| Corrosion Resistance | Coated aluminum wires offer excellent resistance to environmental factors. | Outdoor applications including power lines and telecommunications. | Longer lifespan and reduced maintenance. |

| Electrical Conductivity | Aluminum has high conductivity, allowing for efficient energy transmission. | High-voltage power transmission lines. | Improved energy efficiency. |

| Cost-effective | Generally cheaper than copper alternatives in terms of material costs. | Manufacturing of electrical appliances and gadgets. | Lower overall project costs for electrical installations. |

| Thermal Conductivity | Aluminum wire can efficiently dissipate heat, mitigating risks of overheating. | Use in electrical systems requiring heat control. | Increased safety and reliability. |

Key Applications of Aluminum Wire Coating in Various Industries

Aluminum wire coating plays a crucial role in various industries. This coating enhances corrosion resistance, making aluminum wire suitable for outdoor applications. For instance, in the construction sector, aluminum-coated wires are vital for electrical wiring. A report from the International Wire and Cable Association states that demand for coated wires is expected to rise by 15% over the next five years.

In the automotive industry, aluminum wire coatings are used in battery cables and electrical systems. The lightweight nature of aluminum contributes to fuel efficiency. The Global Automotive Industry Report highlights that coated aluminum wires can reduce vehicle weight by up to 20%. This factor is increasingly important as manufacturers strive for sustainability and lower emissions.

However, challenges remain. The adhesion of certain coatings can be inconsistent, leading to potential reliability issues. This inconsistency can affect performance in high-temperature environments. As industries innovate, addressing these shortcomings is essential. The future of aluminum wire coatings hinges on improving durability and performance under extreme conditions.

Comparative Analysis: Aluminum vs. Other Wire Coating Materials

Aluminum wire coatings have gained popularity due to their unique benefits. Compared to traditional materials like copper and PVC, aluminum offers advantages in weight, conductivity, and cost-effectiveness. A report by the International Aluminum Institute indicates that aluminum is 70% lighter than copper, reducing transportation costs and energy consumption in production.

While aluminum has its benefits, there are drawbacks. For instance, it is more susceptible to corrosion when exposed to moisture. In contrast, PVC coatings provide a stronger barrier against environmental factors, but they may not offer the same level of conductivity. A study from the Electrical Wire Association shows that coated aluminum can have conductivity levels around 61% that of copper.

Another point of comparison is thermal performance. Aluminum coatings can handle higher temperatures than PVC. Yet, they may not withstand extreme conditions as well as some specialized coatings. A report by Global Insights suggests that specific environments may require multi-layer coatings for optimal performance.

Tip: Always assess the operational temperature range before choosing a coating. Proper assessment ensures safety and efficiency.

Innovative Technologies in Aluminum Wire Coating Processes

Innovative technologies in aluminum wire coating processes are rapidly evolving. These advancements improve the performance and durability of wire used in various applications. A recent industry report indicates that the global aluminum wire market is expected to grow at a CAGR of 5.4% from 2023 to 2028. This growth is largely driven by increased demand in electrical applications and the construction sector.

Modern coating techniques, such as electrostatic spraying and powder coating, enhance adhesion and resistance to environmental factors. They offer superior insulation properties that help in reducing energy losses. In fact, wires with advanced coatings can exhibit a 20% increase in energy efficiency compared to traditional methods. Yet, challenges remain. Some manufacturers still rely on outdated processes. This can result in inconsistencies in product quality and performance shortcomings.

Furthermore, the sustainability of coating materials is a growing concern. While many manufacturers are adopting eco-friendly coatings, the transition is not uniform. Industry stats suggest that less than 30% of companies have fully integrated green technologies in their coating processes. This calls for a reevaluation of practices to align with environmental goals. Striking a balance between innovation and sustainability remains a critical challenge for the aluminum wire industry.

2026 Top Aluminum Wire Coating Benefits and Applications

This chart illustrates the various benefits and applications of aluminum wire coating anticipated in 2026. The data highlights the major advantages that increase the efficiency, durability, and utility of aluminum wire in various industries.

Environmental Impact and Sustainability of Aluminum Wire Coating

Aluminum wire coating is gaining traction due to its environmental benefits. According to the Environmental Protection Agency (EPA), aluminum's recyclability can reduce carbon emissions significantly. Using coated aluminum wire in construction and electrical applications can save up to 95% of energy compared to producing new aluminum. Notably, this can lead to a reduction in greenhouse gases.

Moreover, aluminum wire coating is often enhanced with eco-friendly materials. Many coatings are now made from bio-based polymers. This shift not only minimizes the carbon footprint but also maximizes performance longevity. Reports show that coated aluminum is resistant to corrosion and enhances the lifespan of wires significantly. It's a smart choice for industries aiming at sustainability.

However, challenges exist. Some coatings may still contain chemicals harmful to the environment. The industry must focus on developing safer alternatives. The Global Energy Council notes that the market demand for eco-friendly solutions is increasing. Companies need to balance performance and sustainability. Addressing these issues is crucial for the future of aluminum wire coating.